While most businesses are focused on how they can keep the lights on, a few sectors such as manufacturing and biotech are quickly emerging at the forefront of the COVID-19 crisis.

While the pandemic has exposed vulnerabilities in many operating models and supply chains, some businesses are quickly adapting to the new supply and demand. We’re hearing stories of perfume and gin manufacturers shifting to make sanitisers, SMEs producing critical ventilators and other companies repurposing production lines to make face shields and personal protective equipment.

Manufacturers are being forced to innovative and move fast. The pressure of disrupted supply chains and the shortage of medical supplies has created an unprecedented opportunity for our Australian manufacturers to deliver new solutions.

Surviving the outbreak – the race to pivot

The need to create local medical equipment was an immediate response to market demand and a directive strongly supported by government. The question that most businesses have been asking is “how do you change direction at such short notice?” Switching products can be a lot easier and faster than you think.

It’s not about starting from scratch. Manufacturers are looking at how they can reconfigure production lines and through planning and remodelling. While there are challenges for some industries to retool their factories (i.e. automotive manufacturers with complex technologies), some manufacturers have already begun to successfully shift operations.

The latest facts from IBISWorld outline the biggest impacts to our manufacturing sector. With 2% of domestic demand for medical and surgical equipment derived from imports, companies such as Medcon (only surgical facemask manufacturer in Australia) have increased their annual production capacity from 2 million to 50 million. Detmold, a food packaging manufacturer, has announced plans to produce 145 million surgical and respirator masks over the next year. While the spotlight is on medical products, we’re also seeing examples of new Work From Home (WFH) supplies, health tech and supermarket protective equipment being created by manufacturers.

This is a critical time for manufacturers. To outlast cOVID-19 and emerge stronger, manufactures need to diversify and fill the gaps in the market. Pivoting to a new strategy can be done in many ways – either drasticallychanging the whole company or just one or two aspects.

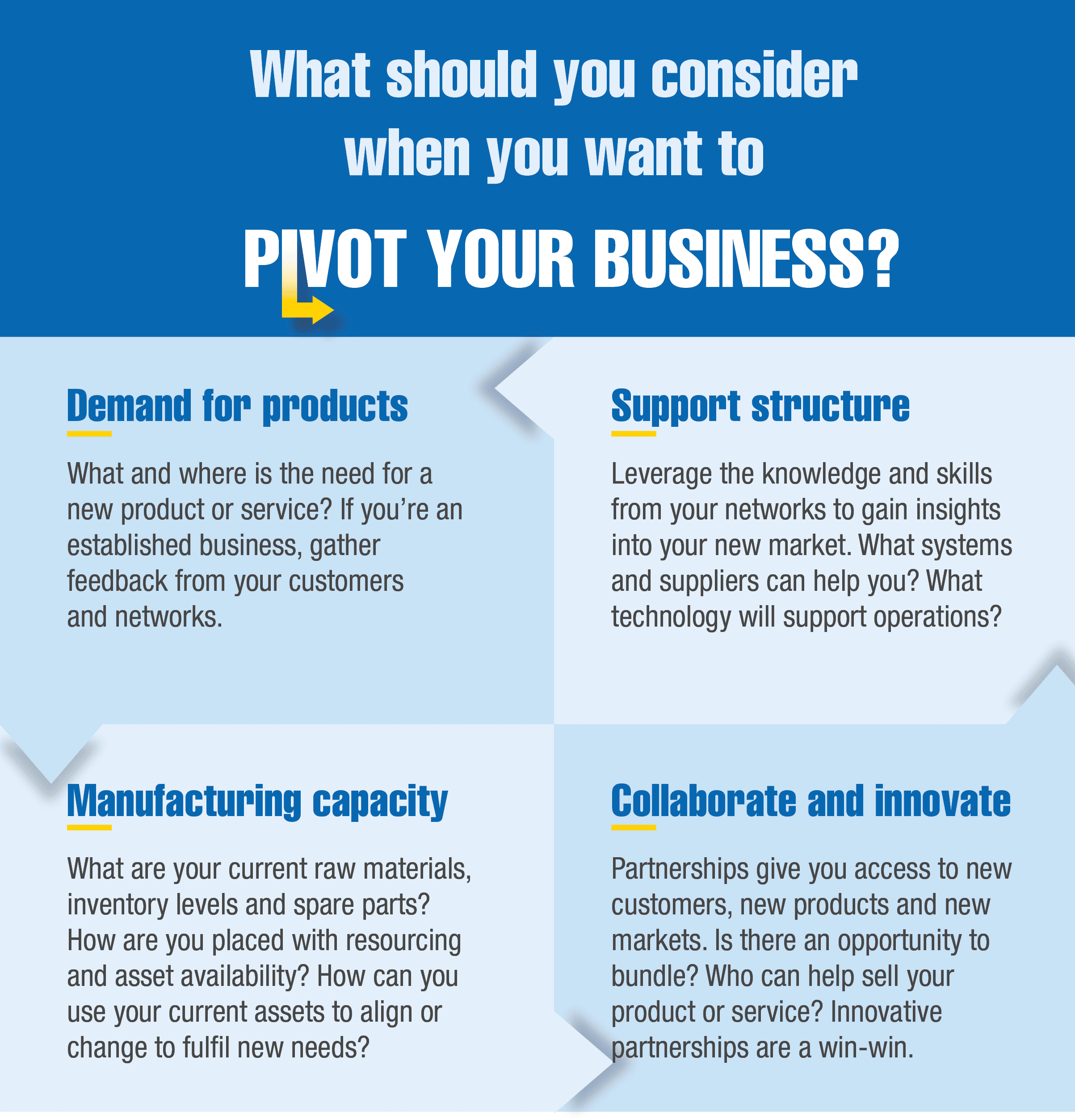

Factors you need to consider

Don’t try to create pivot options in isolation

Innovative businesses have been pivoting for years. The COVID-19 crisis has made it clear that changing your business model is less risky that taking no action at all. If you’re wanting to create new revenue streams, and fast, you need to know your business levers.

Evaluate every part of your business and carefully assess how each will be affected by reinventing products or services. Identify and examine every asset and understand what parts align to the new change. Ask yourself, “What can be re-purposed to create new value?”, “How can you deliver or monetise your product and service?”. Rethink your offering and consider options that will help you to shift fast.

Be open to collaborating with supply chain members and local operators to create a complete solution. Look at the value in your ecosystem – “What can you do with partners that you can’t do alone?”, “Are there options that you would never consider under normal circumstances?”

Pivoting through adversity requires preparation and forecasting. Investing in good business intelligence and data analytics can help you to identify economic trends and future opportunities.